India's #1 Leading Industrial Machin Manufacturer

Menu

Textile Industry

HOME | TEXTILE INDUSTRY

10+

Ultrasonic Experienced

Textile Industry

Ultrasonic technology in the textile industry offers advantages such as precision, speed, reduced material waste, and the ability to work with delicate or heat-sensitive fabrics. It has become an essential tool for enhancing the efficiency and quality of textile manufacturing processes.

- Cutting and Sealing: Ultrasonic cutting and sealing machines are widely used to precisely cut and seal synthetic textiles, fabrics, and nonwoven materials. The ultrasonic vibrations create localized heat at the cutting edge, melting the material and fusing the edges together simultaneously. This process produces clean, sealed edges that prevent fraying and unraveling.

- Bonding and Laminating: Ultrasonic bonding is used to join layers of textiles together without the need for adhesives or sewing. It’s often used in the production of items like disposable medical gowns and diapers. Ultrasonic laminating is used to bond textiles with films or other materials, creating composite fabrics with specific properties.

- Embossing and Quilting: Ultrasonic technology can be employed to emboss patterns or quilting designs onto textiles. It can create raised or textured patterns for decorative or functional purposes, such as enhancing the appearance and texture of fabrics.

- Cutting and Punching Holes: Ultrasonic systems are used for cutting precise holes or perforations in textiles. This is useful for creating breathability in fabrics, making buttonholes, or creating decorative patterns.

- Sewing and Welding: Ultrasonic sewing machines are used to join two pieces of fabric together by creating molecular bonds between them. This method is faster and often more precise than traditional sewing. Ultrasonic welding can also be used to attach fasteners, zippers, or other components to textiles.

- Label and Patch Application: Ultrasonic technology is employed for attaching labels, patches, or logos to textiles. It ensures a secure, durable bond without the need for stitching or adhesives.

- Seam Sealing: In waterproof and protective clothing manufacturing, ultrasonic seam sealing is used to create watertight seals along seams. This is crucial for outdoor gear like rain jackets and tents.

- Embellishments: Ultrasonics can be used to create various embellishments on textiles, such as embossed logos, patterns, or even pleats, adding aesthetic value to the final products.

Features

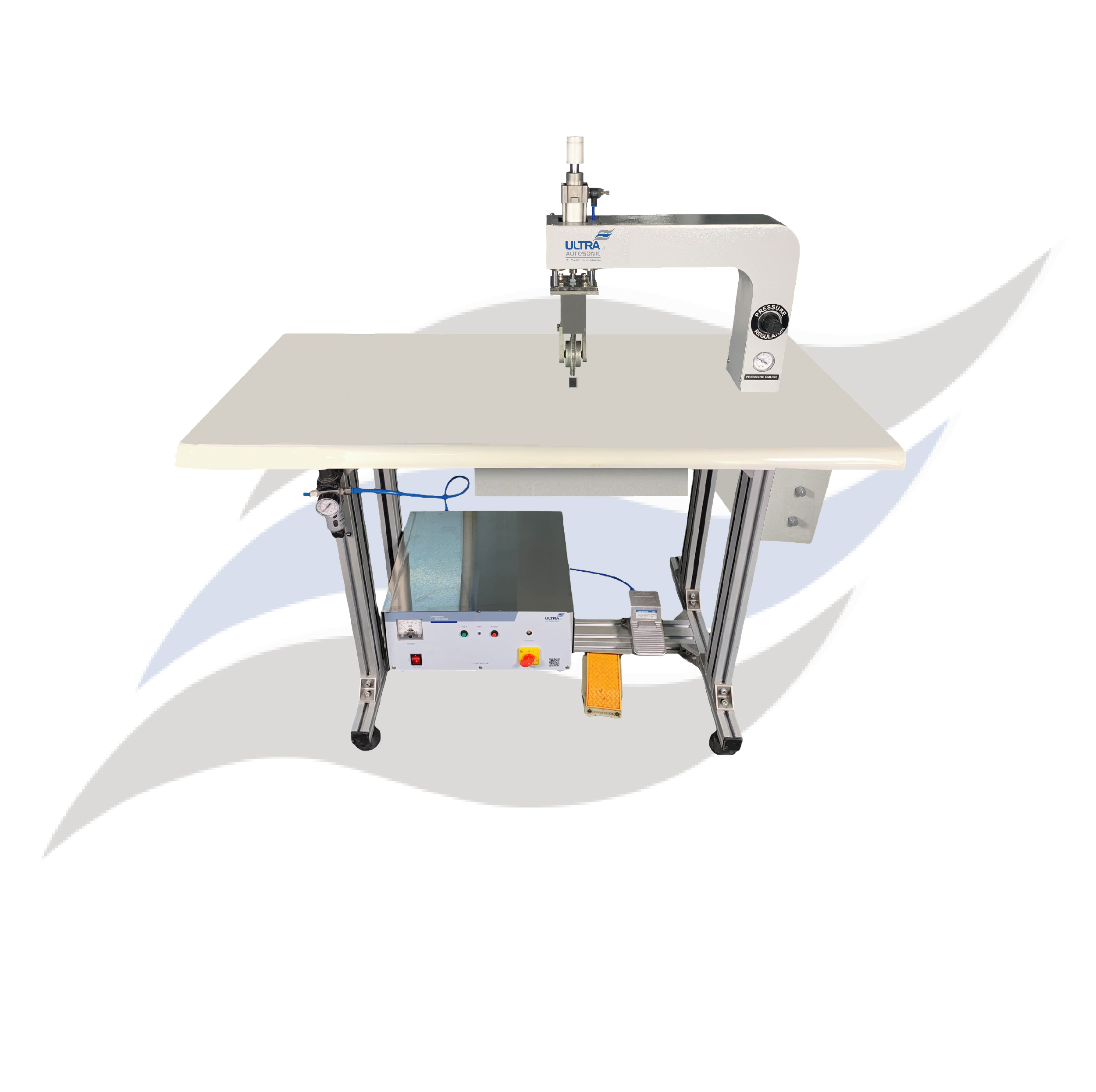

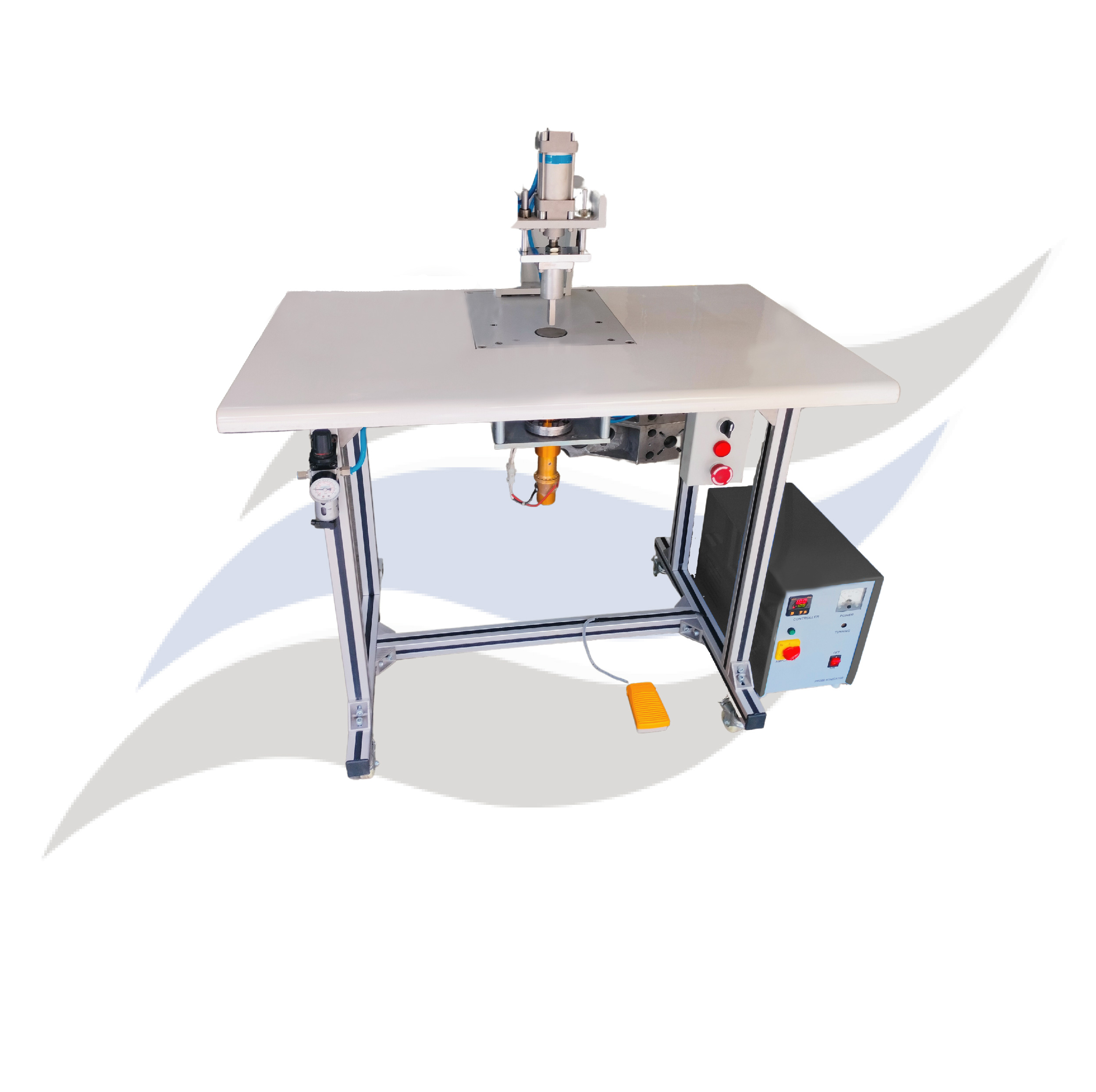

Core Products Textile Industry

24/7 We Are available

We Are Here For Your Help

All Rights Reserved By Ultrasonic- 2023

Contact Form

Download Brochure

Form submit

Get A Quotation